Unique Features:

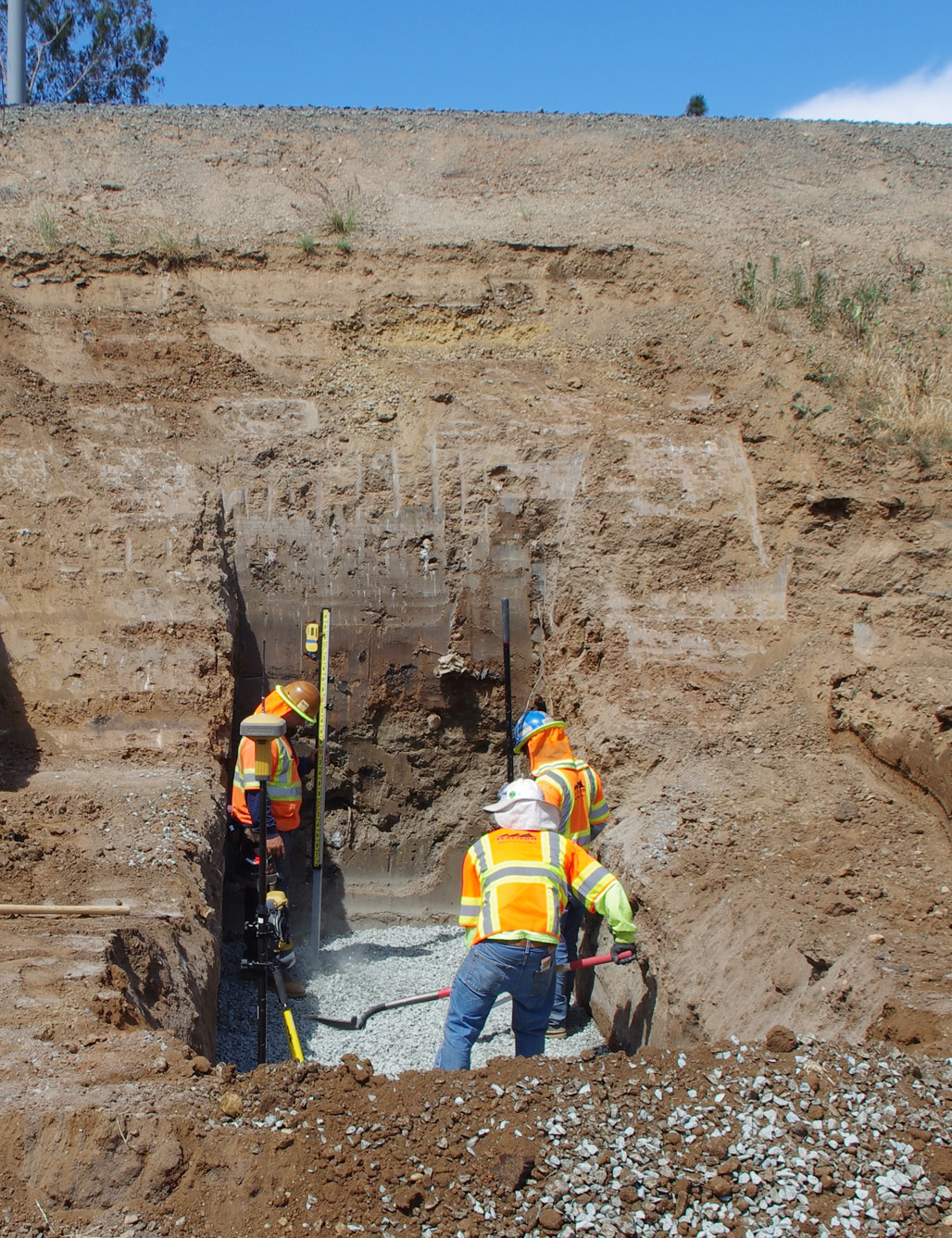

The result of a VECP submittal by Faltiron Construction the Stresswall option was selected due to speed of erection and cost savings due to elimination of shoring that would have been required for any other wall option at that location. Typical shots show the “slot cut” excavation method wherein the existing emabankment was substantially left in place instead of removal which would have been required for other wall types. By cutting 4″ wide slots into the embankment at 15′ centers the precast counterforts could be placed w/o total wall excavation or any site shoring.

| Area | SANDAG Client | E 80 & LRT Track Support WallWall Scope Of Work |